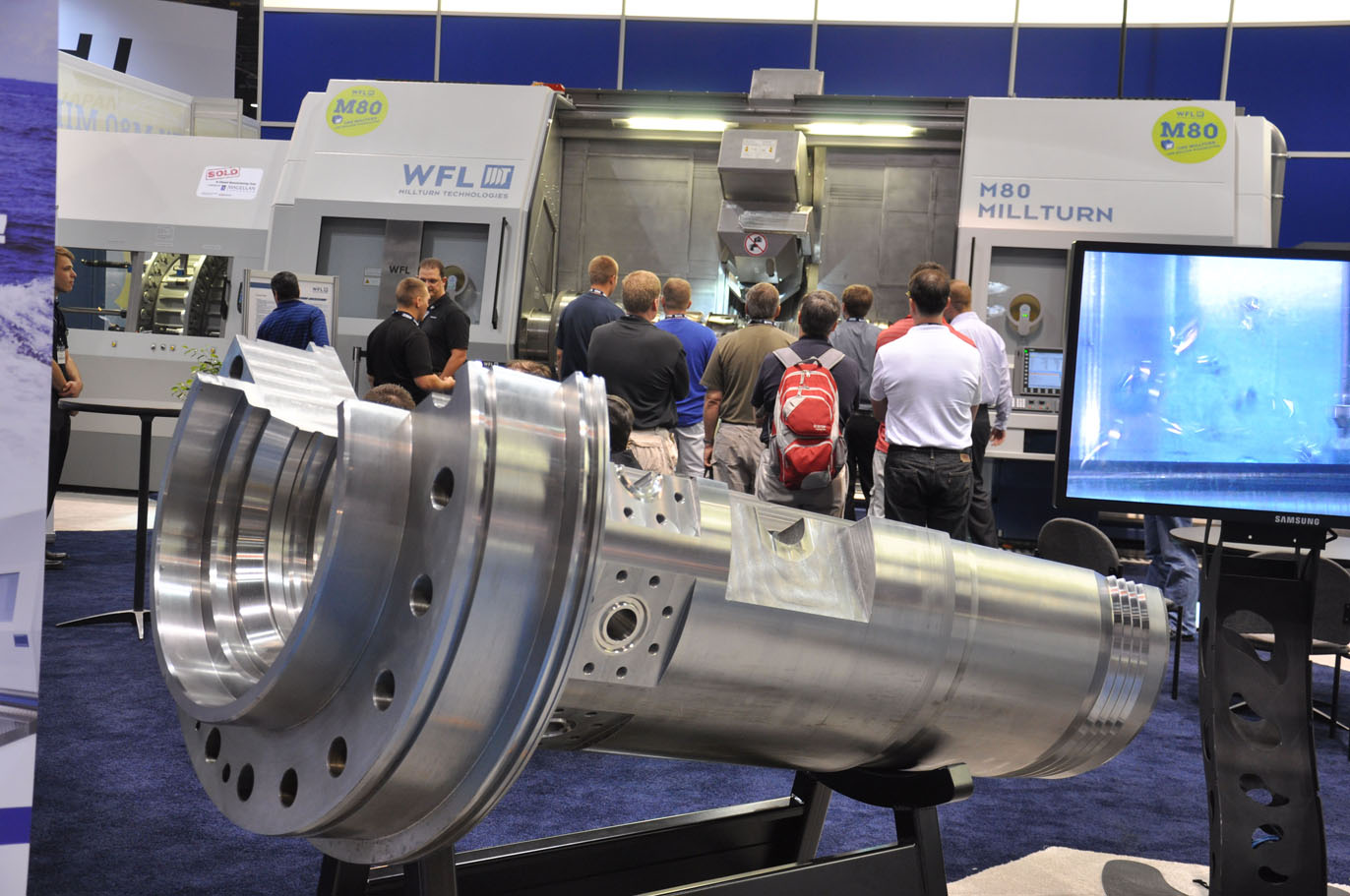

One of the European exhibitors, WFL.

Last week, the Americans had their machinetool party: the IMTS. As one of the few established metal shows, the IMTS succeeded to attract more visitors to Chicago now then two years ago: 100,200 visitors registered. That’s almost a quarter more than two years ago and the highest number in more than 10 years. Is the U.S. industry making a comeback? And what are the other trends?

The manufacturing industry in America is definitely on it’s way back. Investments are growing for the second year now and the Association for Manufacturing Technology expects a further growth in investment.

Asian manufacturers

Whatever surprised me was the massive presence of Asian manufacturers. Not only the well known manufacturers from Japan like Okuma, Mazak and Makino, for whom the North American market is important. No, lesser known manufacturers took off also.There were e.g. more than 100 Chinese exhibitors. The Shenyang Machine Tool Group, the biggest machinetoolbuilder in the world but with 95 percent of their sales within China, was in Chicago with a booth that perfectly would fit to the EMO. They showed a whole series of smaller and larger lathes and milling machines and machining centers that in all respects look clearly better then some years ago. SYMG ceo Xiyou Guan wants to sell al lot more machines in the Western markets. In stead of 5 percent outsite China now, that number has to become 30 percent in a few years. The company is very ambitious.

German industry hammered

But also Taiwanese and Korean machinetoolbuilders are looking to the Western markets. Hyuandai WIA ceo In-Kyu Bae said that the group wants a place in the top 5 global brands in this market. It is clear that the Asian machinery industry wants more market share in the world. Does the German machinetoolbuilding industry get hammered between declining investment in China and increasing competition from Asia? For sure their were a lot of German exhibitors, even smaller companies are expanding internationally. They see the revival of the American industry and want their piece of it. Speaking to German manufacturers, they always say that Chinese machinetoolbuilders will not reach the German high tech level within a decade of more. But guys: European brands like DMG, AgieCharmilles and Hermle, are introducing special machines for customers who don’t need the most advanced technology. Isn’t that the same market the Asian competition is focussing on?

Made in America

Is the role of the U.S. engineering industry over? In Europe, we think that HAAS Automation is the only remaining machinetoolbuilder in the U.S.. But there are several smaller players. And: Mazak had this year than 9 machines at their booth wich were developed and built in Kentucky. This autumn Mazak starts exporting some of these machines from the U.S. to e.g. Europe. “This confirms the fact that the U.S. is a very competitive environment remain for advanced technology products,” said CEO Brian Papke Mazak U.S..

Robots

Automation is in the U.S. is far from such a theme as in particular the Dutch shows. Solutions such as Dutch companies Cellro, BMO, Car Cell and RFA show, haven’t I seen in Chicago. A nice application was seen at the booth of Modern Industries, the manufacturer of MPower, producer of modular fixtures. Here the two armed humanoid robot from Yaskawa changed clamping tools.

Digital world

What I also noticed is that the real innovation is increasingly in the digital world. Okuma is one of the advocates for open controls. On their booth there were different partners who have developed applications that integrate seamlessly with the Okumacontrol and give insight into the efficiency of the machine, energy consumption, service life of the tools etc. Opposite the openness of Okuma to third parties access to the control is the closeness of Samsung. The Korean group showed in Chicago a system that connects the machines to the iPhone, iPad and Android smartphone. Simultaneously, with even the option to remotely stop the machine and start agian. With the camera you can watch on your smartphone what is happening around the lathe. Or can the service engineer in Samsung watch when a customer calls the helpdesk. Very nice in an era of light out machining. But will closed systems survive? The Samsung employee himself actually gave the answer: Fanuc did not cooperate to remotely switch the CNC-maschinetool on and off . “Because we’re so deep in the control, we’ve got the signal out of the control by ourself.”